SCREW CONVEYORS

Around the world, Orthman screw conveyors are handling everything from alfalfa meal to zinc oxide

The productivity of your bulk material manufacturing operations ultimately depends on the speed and efficiency of your equipment supplies. That’s why so many companies rely on Orthman screw conveyors and components for a wide variety of applications, including distributing, collecting, mixing, heating and cooling, elevating, batching and aerating.

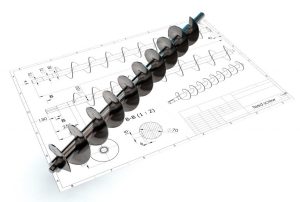

Because Orthman uses a standardized set of parts, screw conveyor systems are economical and easy to maintain and can be configured in a variety of ways to deal with process variants inclines and multiple discharge locations. Components can be enclosed for sanitary construction and constructed for a variety of materials.

Orthman screw conveyor systems and parts are readily available and supported by a responsive service network Orthman screw conveyors can be furnished with all necessary power transmission components, including V-belts, sheaves, motors and guards, all precision-designed to work with the screw conveyor drive.

Elevate Material Handling Efficiency with Versatile Screw Conveyors

Orthman’s screw conveyors are globally recognized for handling a vast array of materials, from alfalfa meal to zinc oxide, epitomizing versatility and reliability in bulk material handling. They are fundamental to the productivity of bulk material manufacturing operations, offering unparalleled speed and efficiency, a prime choice for a myriad of applications including distributing, collecting, mixing, heating, cooling, elevating, batching, and aerating.

Orthman’s use of a standardized set of parts ensures that the screw conveyor systems are not only economical but also easy to maintain. These systems can be configured in various ways to accommodate process variations, inclines, and multiple discharge locations. The components can be enclosed for sanitary construction and can be constructed of diverse materials, such as stainless steel and carbon steel, making them suitable for different types of screw conveyors, including horizontal and vertical screw conveyors.