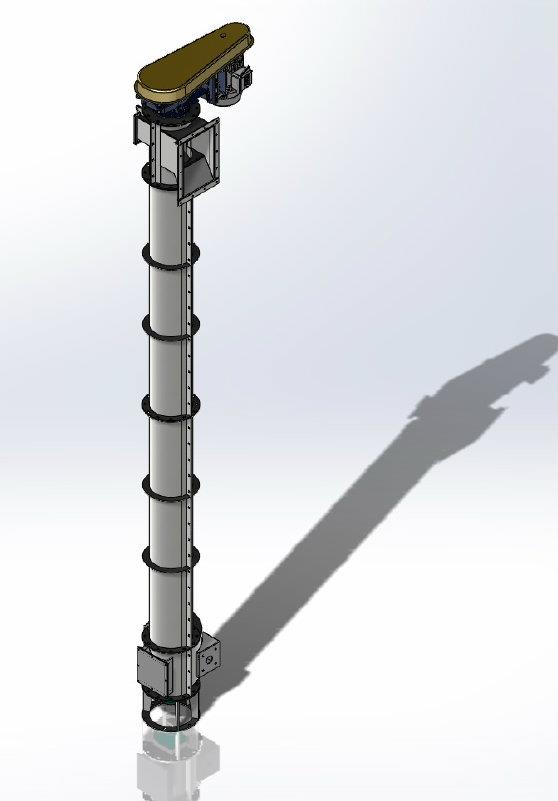

Vertical Screw Conveyors

Our vertical screw conveyors come equipped with several integral components, each designed to perform seamlessly and ensure the longevity and reliability of the system.

- Comprehensive inlet section

- Durable head section

- intermediate sections

- Strong pedestal

- High-quality screw

- Efficient drive unit

- Adaptative feeder screw

Orthman vertical screw conveyors offer numerous operational benefits, making them a preferred choice for various industrial applications.

- Advanced and efficient design

- Simple installation process

- Compact requiring less space

- Economical and cost-effective

- Option for a dust-tight system

- Flexible material discharge in any direction

- Capable of up to 40’ of elevation

Our vertical screw conveyors are versatile, serving a range of industries and materials with reliability and precision.

- Animal Feed

- Pet Food

- Food Processing Industries

- Ice Handling

- Pellet Transportation

- Bone & Blood Meal Handling

The design of our vertical screw conveyors is the epitome of innovation and precision, aiming to fulfill every operational demand efficiently.

- Capacity ranges between 400 to 6,000 cubic feet per hour

- Optional internal bearings available but not recommended

- Typical vertical speeds are between 150 to 250-rpm

- Equipped with “kicker” paddles at discharge

- The discharge height is limited to about 50-feet

- Requires lateral support at the drive end

- Horizontal feed screw is 45-percent loaded

- Horizontal and verticals are typically of the same diameter

- Necessary lateral supports to structure every 10 to 12-feet